210k BTU Titanium Tube and Shell Heat Exchanger for Saltwater Pools/Spas ss

210k BTU Titanium Tube and Shell Heat Exchanger for Saltwater Pools/Spas ss

210,000 BTU Titanium Tube and Shell

* Same Side Ports

* GPM Boiler Side – 9.13

* GPM Pool Side – 63.94

* Boiler Ports – 11/2" NPT

* Pool Ports - 1 1/2" NPT

* Port to Port - 13 1/4"

* Diameter – 3 3/16"

* Length – 20"

* Number of Tubes - 30

* PSI Drop Hot – .38

* PSI Drop Cold – 1.06

* Working Pressure - 80 PSI

* BTU rated with 180F Boiler and 80F Pool

This unit is suitable for pools/spas that are 18,060 gallons.

These heat exchangers are constructed with a Titanium shell and Titanium corrugated inner tubes to ensure high velocities inside the unit.

This is a very reliable, efficient and cost effective way to transfer heat indirectly between any boiler circuit and any pool or spa circuit.

The units are designed for both horizontal and vertical mounting. Port sizes: (to/from Boiler) 1 1/2" - (to/from Pool) 1 1/2".

It is recommended to always install the unit with the mounting bracket (mounting brackets included with each unit) fixed to a wall, and/or ceiling or floor to prevent water hammer or vibrations which could damage the unit.

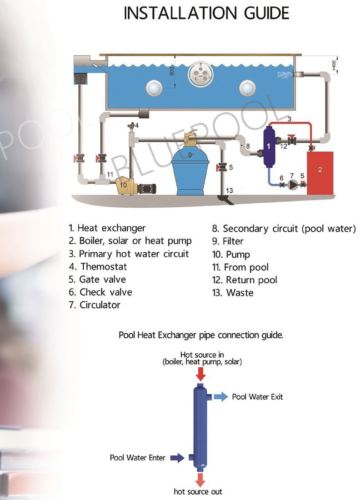

IMPORTANT!! Always install the Titanium Pool & Spa Heat Exchanger in a counter flow pattern.

-

The units should be installed downstream of the filtration and pumping equipment. The boiler water must be assisted and the usual precaustions taken to prevent air locks.

-

The pool water pump should be controlled by a thermostat in the pool pipe work before the heat exchanger and set at the required temperature.

-

Titanium Pool and Spa Heat Exchangers are suited for a large range of chemical environments and conditions, due to a thin, invisible, but extremely protective surface oxide film (primarily TiO2).

-

Titanium is especially known for its elevated resistance to localized attack and stress corrosion in aqueous chlorides (e.g., brines, seawater) and other halides and wet halogens (e.g., wet CI2 or CI2 sat, brines), and to hot, highly oxidizing, acidic solutions (e.g., FeCI3 and nitric acid solutions). Titanium is also recognized for its superior resistance to erosion, erosion-corrosion, cavitations and impingement in flowing, turbulent fluids.

Note:

1. For occasional (holidays & weekends) use pools we recommend a 2x output multiplier to obtain a 2°F/hr heat up rate;

- Hot tube heating

- Floor heating

- Driveway snowmelts

Typical industrial application:

- Oil cooling or heating

- Steam condenser

- District heating

- Transmission and engine cooler

- Boiler sample cooler

- Waste water heat recovery

- Industry process applications

IMPORTANT!! It is the purchaser's responsibility to ensure that all fluids in contact with the products are compatible with the construction material of the product, this includes operational fluids and cleaning fluids.

Corrosive environments are often a combination of chemical levels, flow rates and temperatures. Failure to ensure this will result in damages to the product.

We provide a limited lifetime warranty against manufacturer defects.

***We will ship to Alaska/Hawaii...please call for shipping quote***

Product features

Product features

Materials and care

Materials and care

Merchandising tips

Merchandising tips

Share